Wiring up your first electric guitar kit is a thrilling experience, especially when you start imagining plugging it in and pulling off those first riffs. But along the way, it’s pretty common to hit a few snags. That’s why it’s worth knowing the most common wiring mistakes and how to fix your electric guitar kit before you even pick up the soldering iron. Most of these hiccups can mess with your tone, but the good news is they’re usually easy to track down and fix with just a few basic tools and a little patience.

Why Guitar Wiring Matters for Your Kit Build

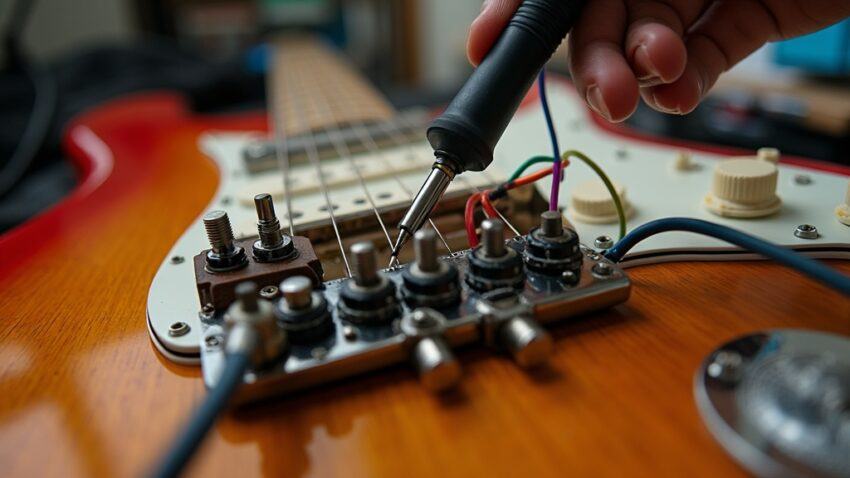

Getting the wiring right in your electric guitar kit can make all the difference in how it feels and sounds when you play. Those wires decide how your pickups, knobs, and switches send the signal to your amp — and if something’s off, you’ll hear it. Bad wiring can mean anything from annoying crackles and weak volume to total silence. Even if you’re brand-new to soldering, learning the basics of how your guitar’s electronics fit together goes a long way. Plus, it’s a skill you can use later if you ever want to tweak or upgrade your guitar.

For first-time kit builders, wiring mistakes are almost a rite of passage. The symptoms? Buzzing, humming, or a guitar that just refuses to make a sound. Knowing what’s normal for electric guitar wiring—and how to fix what’s not — can save you hours of frustration, whether you’re assembling a fresh kit, breathing life into a bargain find, or just curious about what’s going on under the pickguard.

The Most Common Wiring Mistakes (and How to Fix Them)

- Cold Solder Joints: You’ll notice these as dull, lumpy connections rather than the shiny, smooth look you want. They don’t conduct electricity well, which shows up as crackling or complete dropouts. If things crackle when you move a knob or jiggle a wire, go back, heat the bad solder joint, add a bit more solder, and let it cool without moving it.

- Wrong Wire Connections: Accidentally swapping two wires can break the whole circuit. Double-check your kit’s wiring diagram — these are easy to find online for Strat, Tele, or Les Paul builds. Use different colors or a bit of tape to help track which wire goes where.

- Poor Grounding: Bad grounding is one of the most common causes of unwanted buzz or hum. Make sure the bridge and all the pots (volume and tone controls) are well grounded. Your output jack sleeve (the part that touches the outside of the cable) should also tie into ground.

- Extra Long Wires: Leaving wires longer than needed creates a spaghetti mess that can cause accidental shorts or let hum sneak in. Cut wires so there’s enough slack to move but not so much they cross over or touch places you didn’t mean them to.

- Burned or Melted Parts: Too much heat from the soldering iron can fry or melt plastics and damage components. If a pot feels rough or you spot melted plastic, swap it out. For switches and jacks, don’t linger with the iron: solder quick and let things cool.

All these mistakes are fixable. If you move patiently and tackle things step-by-step, you’ll dodge headaches when you finally plug in and want to play.

** Here’s a little transparency: Our website contains affiliate links. This means if you click and make a purchase, we may receive a small commission. Don’t worry, there’s no extra cost to you. It’s a simple way you can support our mission to bring you quality content. **

As an Amazon Associate, I earn from qualifying purchases.

What Type of Wire Should I Use?

Most electric guitars use stranded, cloth-covered, or PVC-insulated copper wire between 22 and 24 AWG (American Wire Gauge). You don’t need fancy audio wire — regular pre-tinned hookup wire from an electronics store is all you need. The most popular types are:

- Push-Back Cloth Wire: Easy to use, especially for newbies, because you just push back the cloth instead of stripping insulation. You’ll find this a lot in vintage reissue kits and old-school guitars.

- PVC Insulated Wire: Standard, flexible, and what you’ll see in many modern kits. It needs a wire stripper but resists fraying and holds up well.

Skip solid (single strand) wire if you can, since it breaks easily when you bend it a lot. Stranded wire’s flexibility makes it perfect for the tight spaces inside a guitar control cavity.

Step-by-Step: How to Fix Guitar Jack Wiring

The output jack is where you plug in your cable, and it’s easy to mess up. Here’s a straightforward way to get it working right or fix buzzing/no-sound issues:

- Notice the two lugs on your jack. One is for signal (“tip”), the other for ground (“sleeve”).

- Attach the ground wire from the pots or ground bus to the sleeve tab. That’s usually the longer one connected to the outer ring.

- Run the hot (signal) wire from the volume pot or switch to the tip tab (the smaller one, connected to the inner ring).

- Solder each connection neatly; let them cool and don’t move the wires while they set.

- Give each wire a gentle tug to check it’s secure but don’t yank hard enough to damage the tab.

For a quick test: plug a cable into your guitar, tap the pickups with something metal, and check if your amp picks up the tap. Always test before you screw everything together for good.

Can You Fix an Electric Guitar?

Absolutely. Wiring problems are totally fixable at home if you have a soldering iron, some wire cutters, and a wiring diagram. If the wood’s solid and you have all the main pieces, almost anything else comes down to switches, wiring, and a little know-how. If you hit a snag, take clear photos beforehand so you can retrace your steps easily.

Upgrading and Troubleshooting: Tips for Stronger Sound

- Check Continuity: A multimeter makes it simple to see if your circuit is connected as it should be. If it beeps, your wiring works; if not, you’ve missed a step or wired something wrong.

- Solder Neatly: Heat the solder-iron up for a few minutes, clean the tip, and never rush the job. Tidy solder joints last longer and make future repairs easier.

- Keep a Wiring Diagram Nearby: Even experienced builders like having a reference diagram around. It takes the guesswork out of the process and helps you track down mistakes fast.

Playing Electric Guitar Without a Cable — Is It Possible?

If you try playing a regular electric guitar without a cable, you’ll only hear the quiet acoustic plink of the strings. The pickups’ weak signal needs to get sent to an amp, usually with a cable. Wireless systems work as cable substitutes by sending the signal over radio, but some kind of connection to the amp is always needed. Skip the cable and you lose the electric experience; what’s left is barely louder than an unplugged acoustic.

Extra Stuff to Double-Check Before You Button Up Your Build

- Pots Spin Smoothly: After wiring up, all knobs should turn with no scratchy sounds. If you get a raspy noise, double-check your grounding and try a quick squirt of electronics cleaner.

- Toggle and Blade Switches: Each pickup selector switch should move cleanly into position and give you the right pickups for each setting. It’s easy to wire these wrong, so always test all positions before you screw down the control plate or pickguard.

- Shielding: Lining your control cavity with shielding tape or shielding paint can help cut back on hum. It’s a good idea, especially if you want to play live or use your guitar in places with lots of electrical noise.

What to Watch For

If something buzzes, cuts out, or doesn’t match the diagram, pause and look things over before closing your guitar up. Double-check for frayed wires, solder bridges between tabs, or loose-fitting parts that might work loose over time.

Frequently Asked Questions

Can you fix an electric guitar?

Just about anyone with some basic tools, patience, and internet guides can tackle wiring repairs or upgrades. Fixing bad wiring, faulty jacks, or dodgy switches doesn’t need factory experience. Even first-time solderers can start with a kit and learn as they go.

What type of wire is used in electric guitars?

Most electric guitars rely on stranded copper wire — either cloth or PVC insulated — in the 22 to 24 AWG size. Cloth pushback wire is particularly beginner friendly, as there’s no stripping needed, and PVC insulated wire is common and easy to track down at most electronics shops.

How to fix guitar jack wiring?

Locate the two terminals on the jack. The “tip” is hot (signal), the “sleeve” is ground (usually longer). Hook your ground wire from the pots to the sleeve and your signal wire from the volume pot to the tip. Solder carefully, let everything cool, and check for stray wires or blobs of solder that could cause a short.

Bringing It All Together…

Putting together the wiring on a guitar kit is a great way to get comfortable with your gear and really understand how everything works. Whether you’re chasing down a stubborn hum, cleaning up a messy solder joint, or swapping new pickups in, getting familiar with the basics ensures you’ll spend less time fighting weird noises and more time playing. Mistakes aren’t the end — they’re just another part of learning, and usually a quick fix away from great sound. With a good diagram, a bit of practice, and some attention to detail, you’ll have your guitar gig-ready before you know it.

There are 100’s of ways you can build a business around your passion for guitar building.

Check it out…

This is such a clear and encouraging guide—especially for anyone tackling their first guitar kit wiring. I really appreciate how you demystify common pitfalls like cold solder joints, incorrect wiring, poor grounding, and excess-length wires, showing how these issues often translate into buzzing, hum, or complete dead spots. It’s empowering to know that most of these problems are easily fixable with just a few tools and a steady hand.

I love how you emphasize the importance of using wiring diagrams, testing wiring early before closing up the cavity, and keeping connections neat and tidy—not just for functionality but for future upgrades as well. It’s a reminder that building a guitar is as much about care and precision as it is about creativity.

If there’s one thing beginners tend to underestimate, I bet it’s grounding: that single poor connection can introduce hum and frustration out of nowhere. What other small wiring steps do you find builders frequently overlook, that might later cause weird noises or inconsistencies?

Thank you so much! I’m glad the guide made wiring feel approachable! Getting those basics right really sets the stage for a smooth build and clean tone.

You’re absolutely right that grounding is one of the biggest things beginners underestimate. Another small step that often gets overlooked is tidying up wire lengths and securing loose leads inside the cavity. Wires that shift or touch the wrong points can create intermittent noise that’s tricky to trace later. Also, double-checking solder joints for a clean, shiny connection. Even a joint that looks fine at first can sometimes cause scratchy signals or hum if it’s slightly cold.

Those little details may seem minor at the time, but taking care of them early can save a lot of frustration and really pay off when testing and playing your build.

Thanks again,

~Wayne

This is a really helpful guide. I’ve helped with a couple of beginner kits, and the wiring issues you describe are exactly the problems we ran into. The step-by-step instructions and troubleshooting tips are on time. I’m curious about shielding the control cavity: in your experience, does tape generally work as well as shielding paint, or does it depend on the guitar and pickups? Just wondering before there is another build. Thanks for all the great info here!

Thanks so much! I’m glad the guide resonated and that the troubleshooting tips were on point. Regarding shielding, both copper tape and conductive shielding paint can work well, but there are some nuances. Copper tape is usually easier for beginners, gives consistent coverage, and is great for irregular shapes in the control cavity. Shielding paint can be faster for larger areas and offers good continuity, but it sometimes requires multiple coats and careful grounding. Ultimately, it can depend on the guitar and pickups. Tape often provides a bit more flexibility, especially for smaller DIY kits.

Either method, when grounded properly, can significantly reduce buzz and hum.

Thanks again,

~Wayne