Building a pro-level electric guitar from a kit is not just about putting together some parts; it’s a chance to make a custom guitar that fits your playing style and personality. Whether you’re a hobbyist looking to upgrade your collection or a serious player chasing that next-level cool feel and tone, following a resource like the Best Pro-level Electric Guitar Kit Build Guide can help turn this exciting project into a truly professional instrument.

If you’re anything like me, you’ve probably drooled over legendary guitars and wondered if you could ever own something close. With so many pro options costing a fortune, an electric guitar kit is a super practical way to get that dream instrument without breaking the bank. Plus, there’s a certain satisfaction that comes with strumming those first chords on a guitar you assembled yourself.

This guide shares the steps I use and the tips I wish I’d known on my first few builds. If you want clear advice, cool customization ideas, and answers to common questions, you’ll find them here. Time to grab your toolkit and let’s jump right in.

Plan Your Pro-level Build: What Makes the “Holy Grail” Guitar?

The “holy grail” of electric guitars often refers to legendary models. Think a 1959 Gibson Les Paul or a pre-CBS Fender Stratocaster. These guitars are famous for their feel, sound, and history. For most of us, owning the real deal is like chasing a unicorn. But when you build your own, you can chase after those features that make a guitar legendary, such as the right tone-woods, vintage-style pickups, super comfy neck shapes, reliable hardware, and your own personal touches.

Before starting, get clear on the sort of guitar you really want. Is it a shred machine for solos, a bluesy axe for improv, or a do-it-all workhorse? Write out a list of what you love about your favorite guitars. It helps you pick the right kit and makes every choice, from neck profile to pickups, a lot easier.

** Here’s a little transparency: Our website contains affiliate links. This means if you click and make a purchase, we may receive a small commission. Don’t worry, there’s no extra cost to you. It’s a simple way you can support our mission to bring you quality content.**

As an Amazon Associate, I earn from qualifying purchases.

Choosing a Pro-level Guitar Kit

Not all guitar kits are the same. There are entry-level kits, but for a pro-level build, I look for these:

- Body and neck made from real tone-woods (like maple, mahogany, alder, or ash—not particle board)

- Hardware that doesn’t feel flimsy; look for solid bridges/tuners from brands like Gotoh, Grover, or Hipshot

- Control cavities routed cleanly and neck pockets that fit snugly

- Included electronics, or at least the right cavities and holes for you to install high-end pickups and switches

Names like StewMac, Solo Music Gear, and Warmoth show up a lot in “best kit” lists for a reason. They pay attention to the details that matter. Prices jump a bit compared to beginner kits, but you really get what you pay for.

Are build your own guitar kits worth it? If you enjoy hands-on projects and want a guitar tailored to you, they’re definitely worth checking out. The end result feels unique; the process itself is actually a lot of fun.

Get Your Workspace and Tools Ready

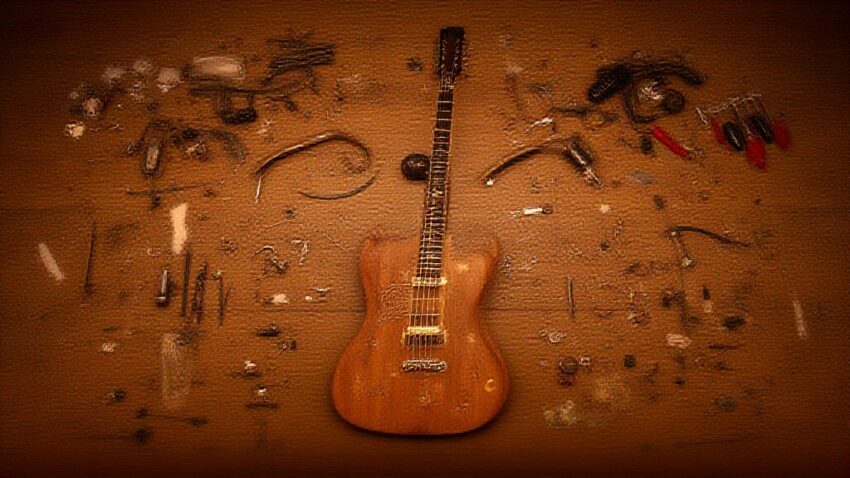

A proper workspace makes your build go way smoother. I lay everything out so I’m not hunting for stuff mid-project. Here’s what you’ll want within reach:

- Sandpaper (in different grits)

- Screwdrivers (Phillips and flathead)

- Soldering iron and solder for electronics

- Clamps for gluing necks and bodies if the kit needs it

- Tuners, bridge, and control knobs (if you’re swapping stock parts for upgrades)

- Masking tape for finishing work

- Wood glue (if your kit uses a set or glued neck)

- Safety gear: gloves, safety glasses, and a dust mask especially if you’re sanding inside

Keeping things organized cuts down on mistakes and lets you focus on building, not searching around the garage for a lost screwdriver. In my experience, spending a few minutes up front to lay things out can save hours of frustration. Think about setting up a designated workspace where you have steady lighting and ventilation—this makes a huge difference during sanding and finishing steps. Some builders even use a simple workbench with a rubber mat to stop parts from rolling away. If you’re planning to assemble multiple guitars over time, investing in a few dedicated containers or organizers for screws, tools, and small parts will pay off.

Full Build Process: Sanding, Assembly, and Customization

Sanding and Prep

I start every build with a good sanding. Even though kits advertise “ready-to-finish,” there are usually rough edges and fuzzy spots around the neck pocket and body. Sanding from 120 up to 400 grit helps me get a silky smooth surface, which really pays off when it’s time for finishing.

Mock Assembly

Dry-fitting all the parts before gluing or screwing anything down is a pretty handy step. This is where I spot fitment issues, like a neck that’s wobbly in the pocket or tuners that don’t line up with the peg holes. Better to find them out now before the glue bottle comes out. Sometimes, a little extra sanding or adjusting is all you need to get things fitting just right.

Finishing

This part is where your guitar takes on its personality. Some folks love a classic sunburst, others go wild with custom paint or even relic finishes to make the guitar look vintage. I always test my stains and paints on scrap wood before going all-in on the body, just to check color and how the finish interacts with the grain.

- Oil finishes (like TruOil) are simple and look awesome

- Nitrocellulose lacquer gives a classic vibe but takes more patience

- Polyurethane is tough and easy to clean

If you’re feeling adventurous, you might experiment with swirling or bursting techniques. Water-based dyes can bring out vivid colors, and layering clear coats can add depth to the grain. A hand-rubbed oil finish is also easier to repair down the road. Remember, finishing is as much about patience as skill — give each coat plenty of time to dry and sand lightly between coats for a flawless result.

Hardware and Electronics

Once the finish dries, it’s time to install hardware and wire up the electronics. High-end pickups from companies like Seymour Duncan or Bare Knuckle can make a huge difference here. Take your time with soldering; bad joints make for scratchy signals and hum you’ll really want to avoid.

Shielding the electronics cavity with copper tape helps keep noise down, which is an upgrade I always add. Think about swapping out the pots and switch if your kit comes with generic ones — a small investment here can seriously boost your sound. When wiring, doublecheck every connection and keep wires tidy to avoid future headaches.

Final Setup

The first string-up is super satisfying. After that, I fine tune everything, setting the truss rod, intonation, pickup height, and action. Don’t rush here; little adjustments make a big difference in feel and tone. If this part feels tricky, plenty of luthier setup guides and videos can help. Having a feeler gauge and electronic tuner handy makes setup more precise. If you want pro results, consider taking your finished guitar to a tech for a one-time setup—then take notes so you can try next time!

Cost Comparison: Is It Cheaper to Build Your Own?

Is it cheaper to build your own electric guitar? The short answer: sometimes. A high-end kit plus quality hardware and pickups can land in the $500–$1,400 range. That’s the price of a nice production guitar, but with a DIY build you’re getting pro-level materials and custom features you won’t get off the rack. Big brands charge a premium for custom shop models with similar specs.

If you already have some tools, or you don’t mind spending on upgrades, the value equation starts to tip in your favor. Plus, there’s the bonus of building something nobody else has. Remember, part of the cost is an investment in your knowledge and skills — each build makes you better and more confident about guitar tech, repairs, and mods in the future.

Who Makes the Best Guitars—and Can You Match Them?

Many players consider brands like Fender, Gibson, PRS, and Suhr as the top tier for pro-level electric guitars. These companies spend years dialing in their designs and use topnotch woods, electronics, and hardware. Some smaller luthiers, like Tom Anderson or Tyler, push things even further with wild attention to detail.

With a well-chosen kit and upgrades, plus some patience and care during the build, you can get surprisingly close to the quality and playability of those big names. While factory guitars might win on resale value and warranty, your custom build offers full control over every bit of look and sound. The key is to focus on the critical areas — wood selection, fretwork, and electronics — since those have the greatest impact on feel and tone. Don’t be afraid to experiment with wiring mods or custom switching, as these can open up new sonic possibilities that off-the-shelf guitars don’t offer.

Quick Tips for a Smooth Build

- Take time with sanding and finishing; the prep work really pays off later

- Check every part for fit before gluing or screwing it down

- Don’t skimp on pickups and hardware; they do most of the heavy lifting for tone and tuning stability

- Watch out for wiring diagrams; lots of helpful ones online if the kit instructions seem skimpy

- Keep a notebook for setup tweaks — it helps if you want to make changes down the road

- Ask for advice from online build communities or forums if you hit a snag

- Always wear a dust mask and eye protection during sanding and finishing, especially with exotic woods

- Doublecheck your work before plugging in the first time

Frequently Asked Questions

What is the holy grail of electric guitars?

Guitarists often use the phrase for classics like the ’59 Gibson Les Paul or vintage Fender Strats and Teles. These guitars are loved for their unique feel, amazing sound, and history. Building your own kit lets you borrow ideas from these legends, such as similar woods or electronics, to get some of that “holy grail” vibe in your custom instrument.

Are build your own guitar kits worth it?

If you enjoy working with your hands, want to learn about guitar mechanics, or want a personalized guitar, they’re absolutely worth checking out. The end result is both playable and something you crafted yourself.

Is it cheaper to build your own electric guitar?

Costs depend on kit quality and any upgrades you add. You might spend a bit more than the cheapest factory guitars, but you’ll end up with higher quality for the price, especially if you use pro-level parts. The experience itself is really rewarding.

Who builds the best electric guitar?

Big brands like Fender, Gibson, PRS, and Suhr are usually at the top of the list for professionals. Putting together your own from a quality kit can get you pretty close, especially if you pay attention to details and don’t skip on the parts that matter most for you.

Moving Forward: Your Custom Guitar Awaits

Building a pro-level electric guitar from a kit is a rewarding challenge. You’ll learn a lot about how guitars work, customize it to your taste, and enjoy the experience every time you play. Check out our Step-by-Step Guide to Building Your First Electric Guitar Kit for a detailed walkthrough.

Start with the right kit, like those in our Best Pickups For Your Electric Guitar Kit: Choosing The Right Tone article, stay patient, and you’ll end up with an instrument you won’t want to put down.

This is your chance to showcase both your style and your skills—learn some finishing techniques in Customizing Your Electric Guitar Kit With Unique Fretboard Inlays to really make it shine.

So have fun, make it yours, and let those new riffs ring out!

There are 100’s of ways you can build a business around your passion for guitar building.

Check it out…